Responsibility for your series production?

We bear it.

Because we guarantee that everything works smoothly.

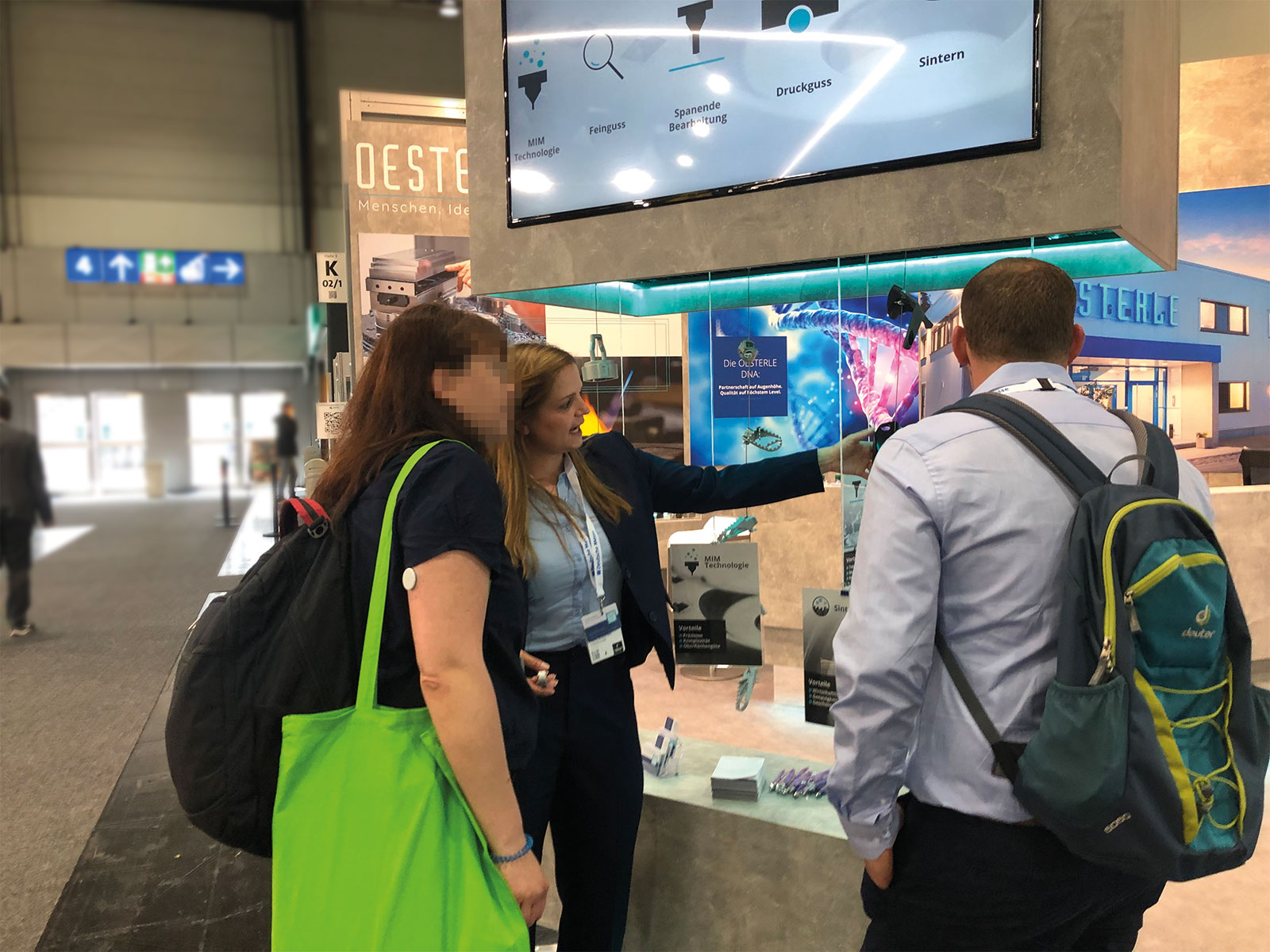

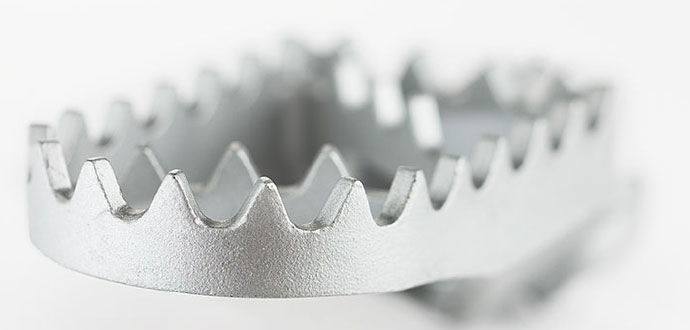

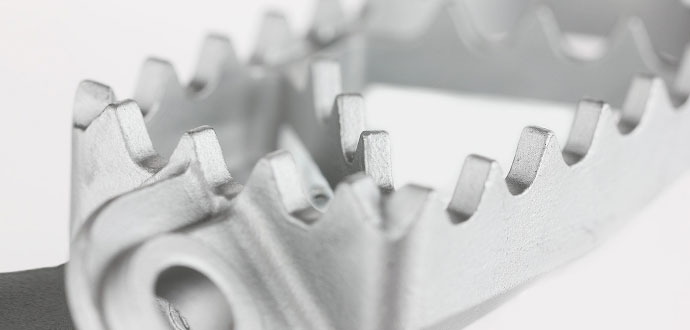

Conscientious quality assurance is part of our daily work and an essential part of the Oesterle DNA. After we serve customers from a wide variety of industries, we align the scope and type of quality assurance comprehensively based on customer requirements. From the standard incoming goods inspection to the 100% serial in-house X-ray inspection, we have the right answer to all our customers‘ questions and requirements!

Standard process

- Incoming goods inspection

- Test report

- Material certificate (spectral analysis)

- Upon customer specification

– X-ray inspection

– Crack testing

– Coating inspection

– Proof of heat treatment

– PPAP

– Etc.

Inspection solutions at the highest level

With our new X-ray system XRH 222-S from a worldwide leading specialist VisiConsult our DIN EN ISO 9712 certified staff offers you inspection solutions at the highest level. With the generated electrical power of up to 225 kV current voltage, it is possible to screen steel up to 25mm wall thickness.

The core of the system is the Xplus X-ray image processing system for non-destructive testing (ZfP / NDT). Here, the focus is on maximum inspection efficiency with the highest image quality (e.g., 5-axis manipulator, live video technology).

Guaranteed safety through state-of-the-art

testing technology

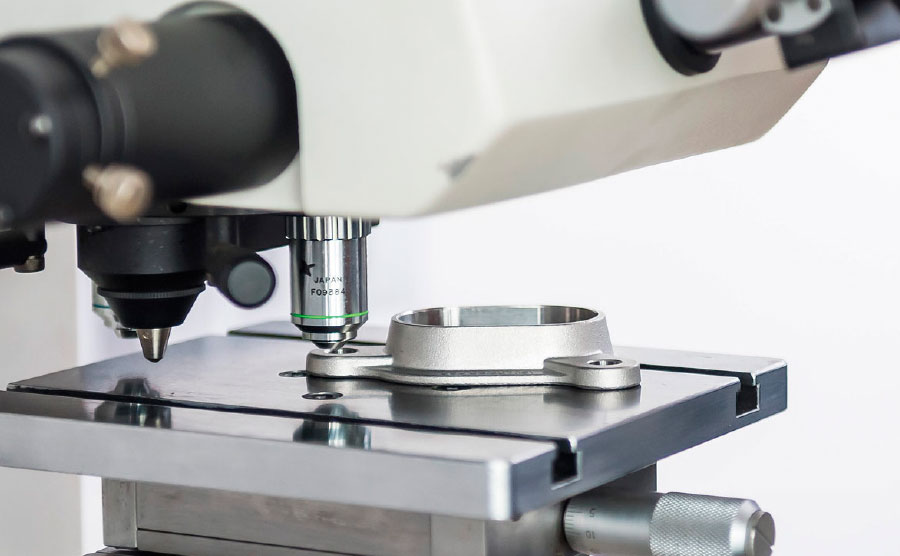

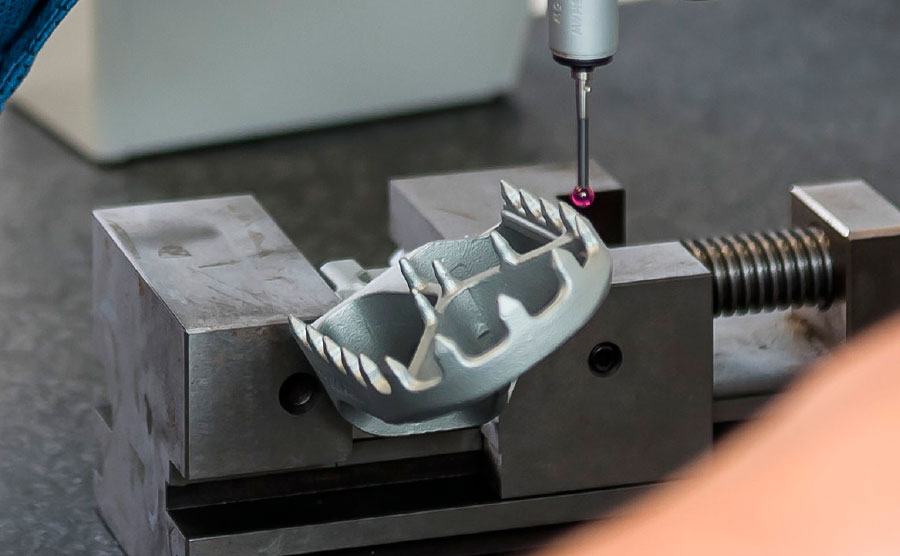

As usual, our in-house quality control offers you guaranteed safety through state-of-the-art testing technology. Our Zeiss measuring machine as well as our Vickers HV hardness tester also enable the highest standards in the testing of all components.

The Oesterle GmbH team will be happy to assist you with technical process support and provide expert advice on the development of your projects.

Get in touch with our contact persons.

Oesterle GmbH and Oesterle Solutions UG (haftungsbeschränkt) are members of the DGZfP (Deutsche Gesellschaft für zerstörungsfreie Prüfung e.V.). Non-destructive testing is an important measure for the quality assurance of materials and is therefore used by us