Die casting – thin parts thick in business

With the die casting process, high precision components from low-melting alloys such as aluminium, zinc and magnesium can be manufactured with very high surface qualities. The process is economically worthwhile, especially for large series.

BENEFITS

- Development, production, just in time delivery

- Thin-walled components

- Complex geometries

- High surface finish

- Most economical casting process for large series

In die casting, the liquid metal is shot through a piston into a divided permanent mold. The sometimes very high pressure loads also allow very thin-walled and complex components without loss of quality. Even with large parts, the mold is filled in fractions of a second, resulting in short cycle times.

If the series size is sufficient, die casting is a highly economical casting process.

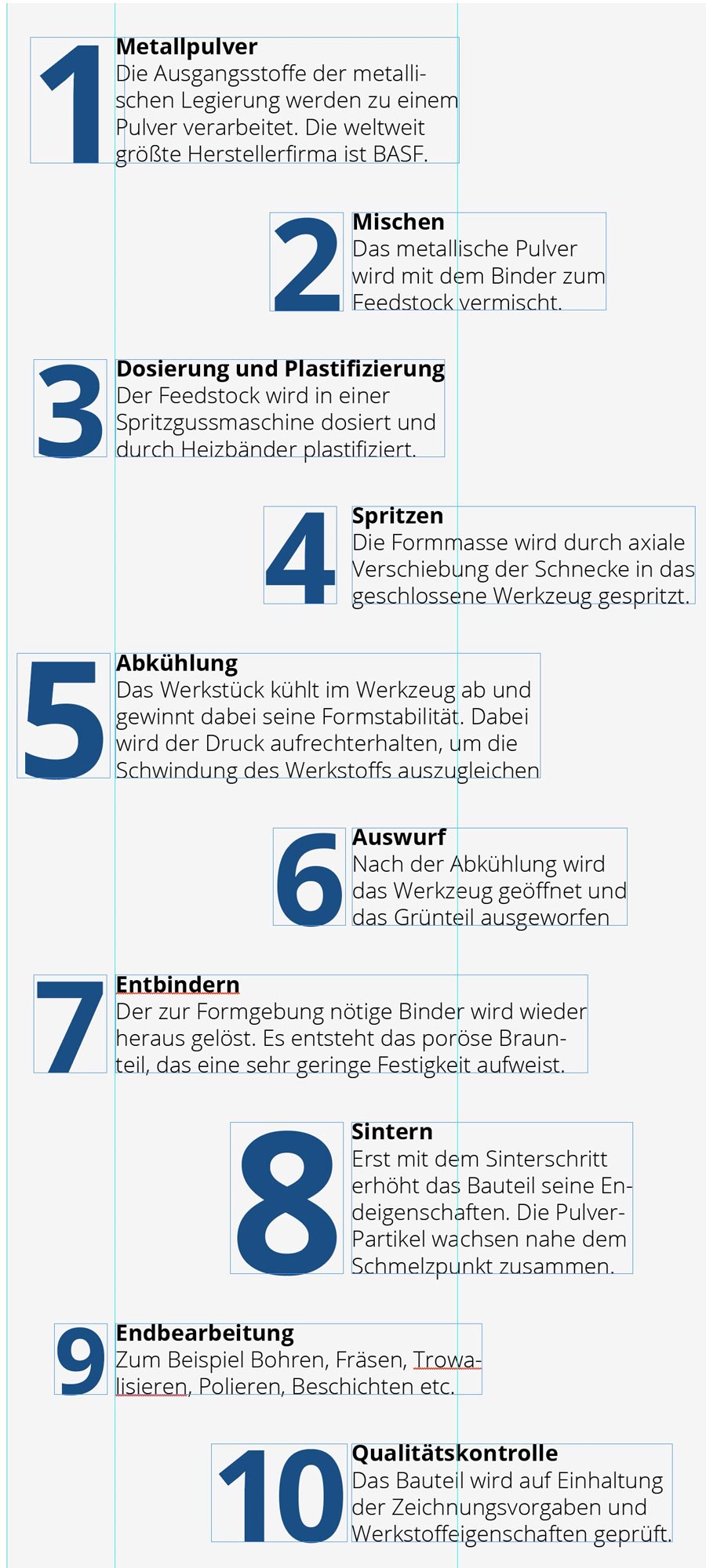

Manufacturing process

Bottom

part coated

Size: 225x92x40 mm

Weight: 383 g

Material: AlSi12Cu1(Fe)

Bottom part coated

assembled

Size: 225x92x75 mm

Weight: 498 g

Material: AlSi12Cu1(Fe)

Coating:

Powder coating coarse

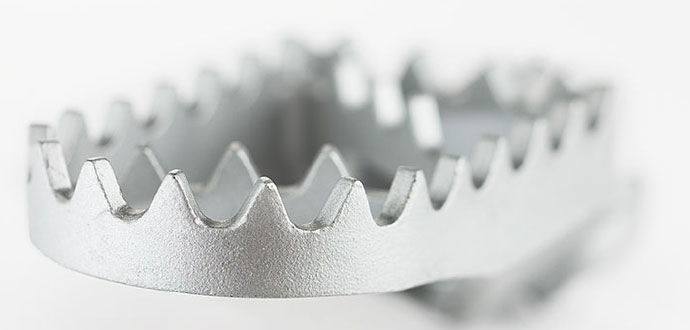

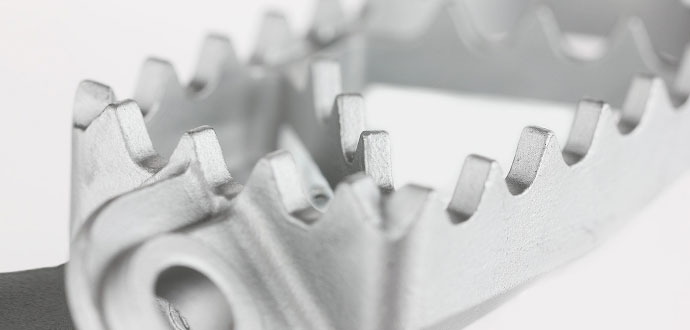

Y-piece

Size: 35x50x25 mm

Wegith: 32 g

Material: ZL102

Door hardware

(black, gold, silver)

Size: 90x65x40 mm

Weight: 235 g

Door hardware

Size: 170x55x30 mm

Weight: 292 g

Material: GDZnAl4Cu1

Cover

Foot protection coated