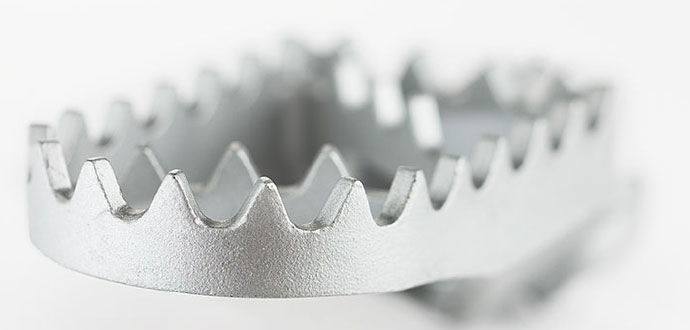

From powder to solid component

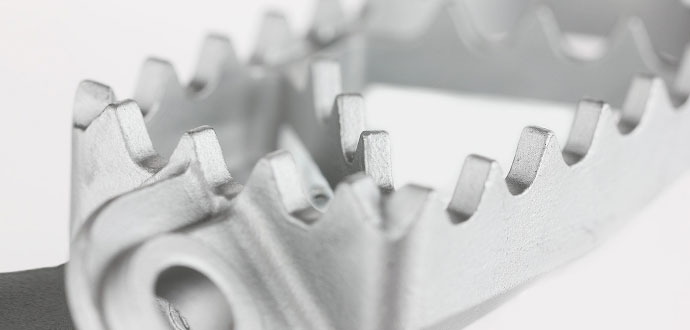

Sintering as a manufacturing process for metallic components is the right choice for workpieces with special geometries, such as compact gear wheels, pinions, bearings or housings, which can be produced ready for installation (also with heat treatment).

BENEFITS

- Development, production, just in time delivery

- No mechanical finishing

- Economical for high quantities

- Narrow dimensional tolerances

- No excess material

Sintering allows shaping without heating the material. The metal powder is pressed into green compacts in matrices at different pressures and sintered in a further step at temperatures just below the melting point. The powder particles melt together at their contact surfaces and the workpiece gets its dimension and design. Due to a final calibration impact, the workpieces have a very high level of dimensional accuracy.

The process is therefore an effective, environmentally friendly and economical process, especially for large quantities.

Manufacturing process

Toothed belt pulley

Size: 43x43x20 mm

Weight: 127 g

Material: FC0208

Locking bow

Size: 60x15x10 mm

Weight: 6 g

Material: Sint C-11

Toothed wheel

Size: 6x5x2 mm

Weight: 0,2 g

Material: CZ-3000

Piston

Size: Ø50x14,5 mm

Weight: 140 g

Guide disk

Size: Ø52x24,2 mm

Weight: 186.6 g