Injection molding for hard

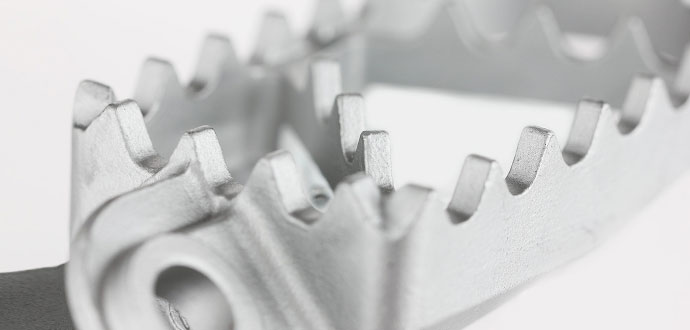

Metal Injection Molding (MIM) is based on the principle of injection molding, which is the undisputed number one in the series production of plastic components. MIM combines the advantages of injection molding with the material properties of metals.

BENEFITS

- Development, production, just in time delivery

- Complex geometries can be realized

- Low tolerances

- Economical for high quantities

By mixing metal powder with a plastic binder, the advantages of the injection process can also be used for metal components. The binder wets the metal powder particles and enables shaping. The binder is subsequently removed and the metal powder is sintered in a vacuum furnace below the melting temperature, thereby shrinking to its final size and achieving its high strength and resilience, which are largely comparable to the solid metal material.

Due to the use of different metal powders, there are nearly no restrictions in the choice of alloy. Assemblies can often be combined into one part.

MIM is the right choice for complex, efficient, fast, environmentally friendly and accurate parts with high surface quality.

Manufacturing process

Shooting unit insert

Size: 15x25x8 mm

Weight: 7 g

Material: 100Cr6

Coating: Cu12-15/Ni2-3

Slider lever

Size: 66x10x11 mm

Weight: 8.82 g

Bevel pinion

Size: 35x20x15 mm

Weight: 13 g

Material: 17-4 PH

Pivot piece

Size: 15x15x5 mm

Weight: 0 g

Material: MIM8620

Product 1085

Size: 23x8,90x6,25 mm

Weight: 4.28 g

Foot brake lever appearance

Size: 44x31x11 mm

Weight: 18.4 g

Appearance gearshift

Size: 52x20x19 mm

Weight: 27.8 g

Cable routing

Size: 10x23x5 mm

Weight: 4 g