Drawing on plentiful resources

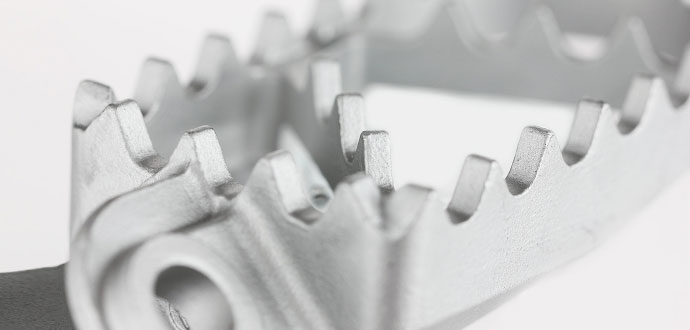

Machining as a manufacturing process for metallic components can be used for all workpieces, but especially for complex requirements. With no lead time for tools, machining enables fast and stable production.

BENEFITS

- Development, production, just in time delivery

- Almost tolerance-free manufacturing

- Economical for prototypes and low volumes

- Flexible, fast machining without tooling costs

- All metals and plastics

The start-up costs are lower compared to other manufacturing processes (e.g., die casting, MIM), so that smaller series and prototypes with tight tolerances can also be manufactured, but often with high economic costs.

Depending on the material and the component geometry, CNC machining can be economical even for high volumes. A high surface finish is achievable. Center-line roughness values in the range of Ra 0.8-3.2 are typical. Values lower than Ra 0.8 can also be achieved.

There are almost no limits to the choice of materials here. As a rule, CNC production has no negative influence on the mechanical properties of the processed materials. Furthermore, the machining of high-strength and hard (even hardened) materials is also possible Due to a high degree of automation and the fact that no tools have to be created, short delivery times are possible.

Manufacturing process

Threaded bush

Size: ca. 30 mm

Weight: ca. 10 g

Stripper

Size: 120x20x5 mm

Weight: 16 g

Material: 1,4401

Aluminum pin blue anodized

Size: 45,3x12x12 mm

Weight: 12.80 g

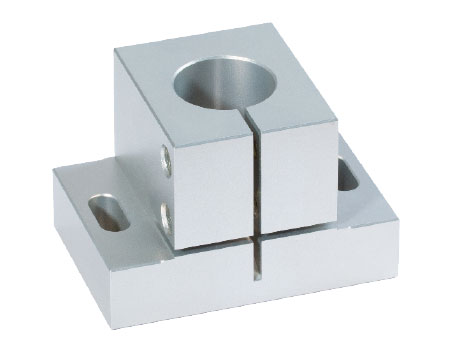

Socket

Size: Ø20x13 mm

Weight: 46.65 g

Unlocking pin

Größe: 65,1x6x6 mm

Weight: 10.3 g

Screw

Size: Ø5,3x13 mm

Weight: 0.69 g

Stand

Size: 50x75x50 mm

Weight: 272.11 g

Valve connection

Size: Ø18,7x24,1 mm

Weight: 9.88 g

Extension

Size: Ø10x70,77 mm

Weight: 30.6 g

Ball switching shaft

Größe: 55x60x85 mm

weight: 379 g

Material: 14,539

Other:

Outer surface polished