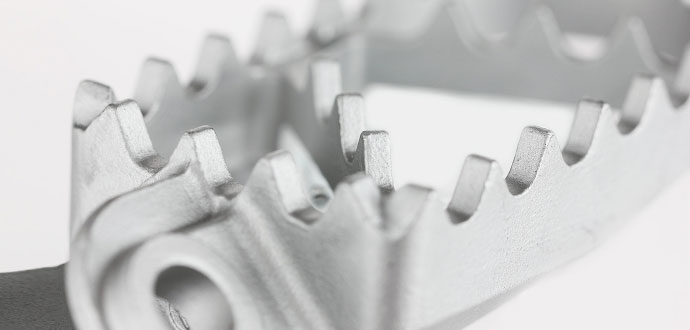

Complexity in one cast

The precision casting (investment casting) production technique is the optimal choice for complex components of almost all sizes. The advantage of the process is, among other things, that parts from smaller batch sizes can usually be cast ready for installation with manageable tool costs and often require little or no mechanical post-processing.

BENEFITS

- Development, production, just in time delivery

- Complex geometries

- No / little post-processing

- High surface finish

- High dimensional accuracy

- Wide range of materials

Castings produced by investment casting, especially by lost wax process, are characterized by their level of detail, dimensional accuracy and surface quality and can therefore also meet the highest customised requirements from a wide variety of industries.

Parts with a typical weight of approx. 30 g up to 200 kg can be produced by investment casting, and a wide variety of materials from steel to aluminium or titanium can be processed.

Manufacturing process

Mounting flange

Size: 67x30x20 mm

Weight: 19 g

Material: ZL101AT6

Coating:

Powder coating fine

Ball switching shaft

Size: 55x60x85 mm

Weight: 379 g

Material: 14,539

Other:

Polished outer surface

Screw nut

Size: 25x35x15 mm

Weight: 32 g

Material: 1,4404

Side stand bracket

Size: 150x100x90 mm

Weight: 440 g

Material: 1,7231

Coating: Zink + KTL

Footrest

Size: 140x60x30 mm

Weight: 263 g

Material: 42CrMo4

Coating: Geomet

Brake cylinder

Size: 132,6x36,5x50 mm

Weight: 122.55 g

Exhaust flange

Size: 78,5x91,5x15,3 mm

Weight: 134.3 g

Flange

Size: Ø60x31,8 mm

Weight: 100 g

Driver

Size: Ø65,5x67,5 mm

Weight: ?

Bracket

Size: 104x35x16 mm

Weight: 102.2 g

Manifold

Size: Ø31x76x22 mm

Weight: 178 g